R&D DEPARTMENT

Each project begins with a joint definition of the product requirements, its purpose and appearance.

After design arrangements, the next steps are technological analyses of selected manufacturing processes, construction of target instrumentation, if necessary, process verification and validation.

USE OF RECYCLATE IN THE INJECTION PROCESS

We are constantly improving and modifying the injection process to adapt the production to the Customer's needs as much as possible. We use the knowledge, experience and skills gained to achieve reprocessing of waste by injection without the need to lower the quality requirements for the products resulting from it. The technological and construction solutions we propose are part of the development of the so-called up-cycling, i.e. giving waste materials new applications and obtaining products with properties not worse than the original ones in secondary processing. Appropriate setting of parameters allows for the best quality of mouldings and enables safe processing of plastics.

ASSEMBLY PROCESS

The high level of industrial automation places ever higher demands on basic processes such as quality and efficiency. When developing technological documentation of the assembly process, we conduct design activities on various levels. Starting from product components, through the design of production processes and manufacturing processes, to cooperation with suppliers and the development of product logistics. Properly developed documentation is the basis for making a technically efficient product, determining the costs of its production as well as organizing and planning production. We define the scope and detail of the created documentation based on the assumed production volume.

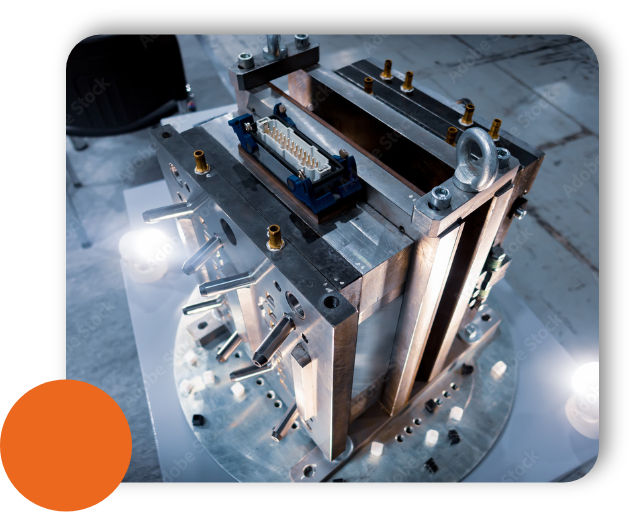

MOULD CONSTRUCTION

We cooperate with toolmakers in Poland and China, which have been our proven partners for years and share our values and goals. In the past, we successfully implemented difficult, demanding projects together. At every stage of product management, we provide professional assistance in concept creation, design, prototyping, assembly, as well as logistics and transport.

OPTIMIZATION OF THE PACKAGING PROCESS

A properly developed packaging process affects the safety of the product in transport, but also the aesthetic and attractive appearance of the package to the Customer. Thanks to a thorough analysis, tests and implemented optimization, we are able to obtain the best solution for a given product. Varied work, most of which is done by hand, is particularly important in the whole chain of activities. Thanks to properly arranged packaging, the goods lying on the warehouse shelves are finally prepared and brought to the state in which they reach the consumer.

REENGINEERING

Fundamental rethinking and radical redesign of company processes leads to ground-breaking improvements in performance. A thorough analysis of the current process or activities, the answer to the question why the process looks like this and how we can modify it, to a complete design from scratch, allows you to achieve an improvement of at least 25%. The introduced changes bring a specific benefit to Customers.